It started with a sketch in a notebook.

With no design or construction experience to speak of, Dr. Nga Lee (Sally) Ng, an assistant professor in Georgia Tech’s Schools of Chemical & Biomolecular Engineering and Earth and Atmospheric Sciences, designed and built a one-of-a-kind aerosol research space in the Ford Environmental Science & Technology (ES&T) Building in under two years. While we know that aerosols, which are essentially nanoparticles suspended in the air around us, influence both the environment and our health, little is known about how human activity affects aerosol formation or evolution. Ng hopes to change that by studying how biogenic and anthropogenic aerosols react and interact with each other, but to do that she had to build something that has never been built before.

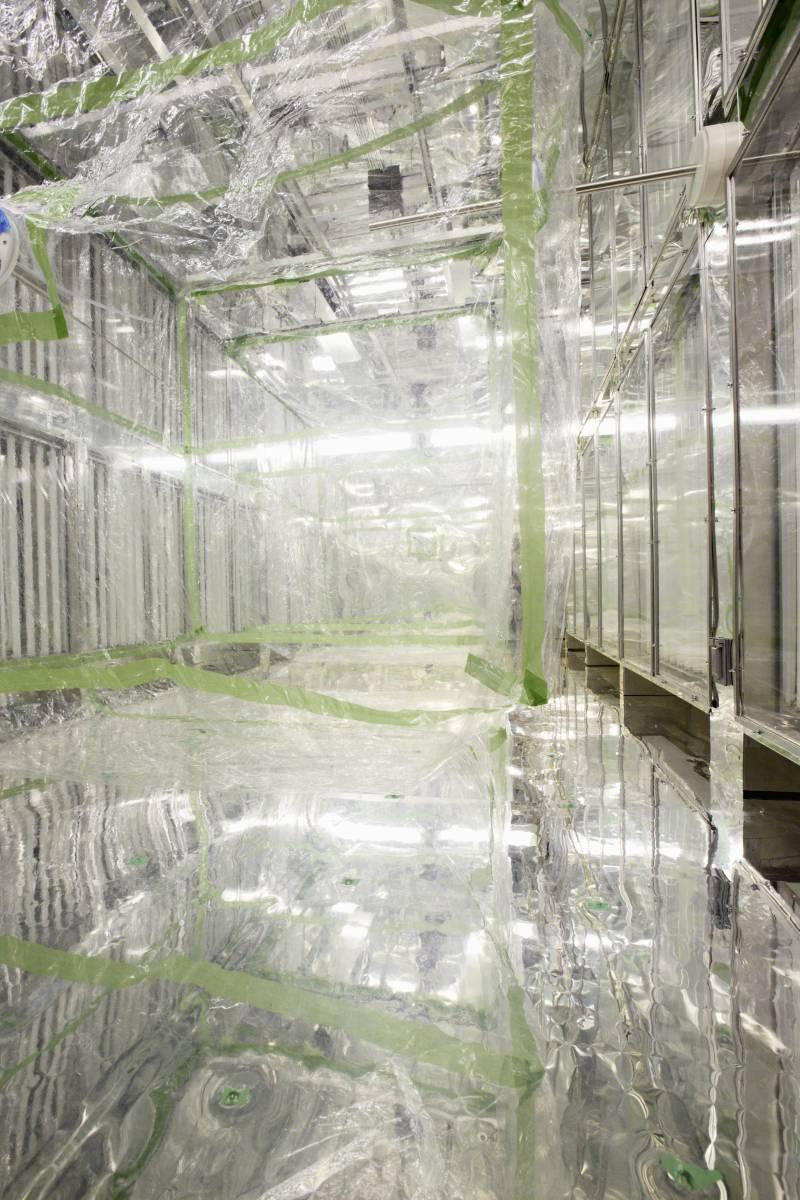

The Georgia Tech Indoor Chamber Facility (GTICF), as it has been named, is a 21x12 foot climate-controlled enclosure. It houses two flexible Teflon chambers suspended from the ceiling, which are surrounded by both UV lamps and sunshine fluorescent lamps, and is a strange and beautiful world unto itself. The array of lights surrounding the chambers allows Ng and her staff to conduct research under conditions never before studied. The existing body of aerosol research has been confined to the UV range and a standard temperature of about 20 degrees Celsius.

Thanks to the unique light setup and the precise climate controls, the GTICF is the only facility in the U.S. that can generate aerosols under low temperatures and a light spectrum that captures the full range of photochemistry in a well-controlled environment. This provides a unique opportunity to investigate aerosol formation and chemical and physical properties under conditions that were not previously accessible to researchers.

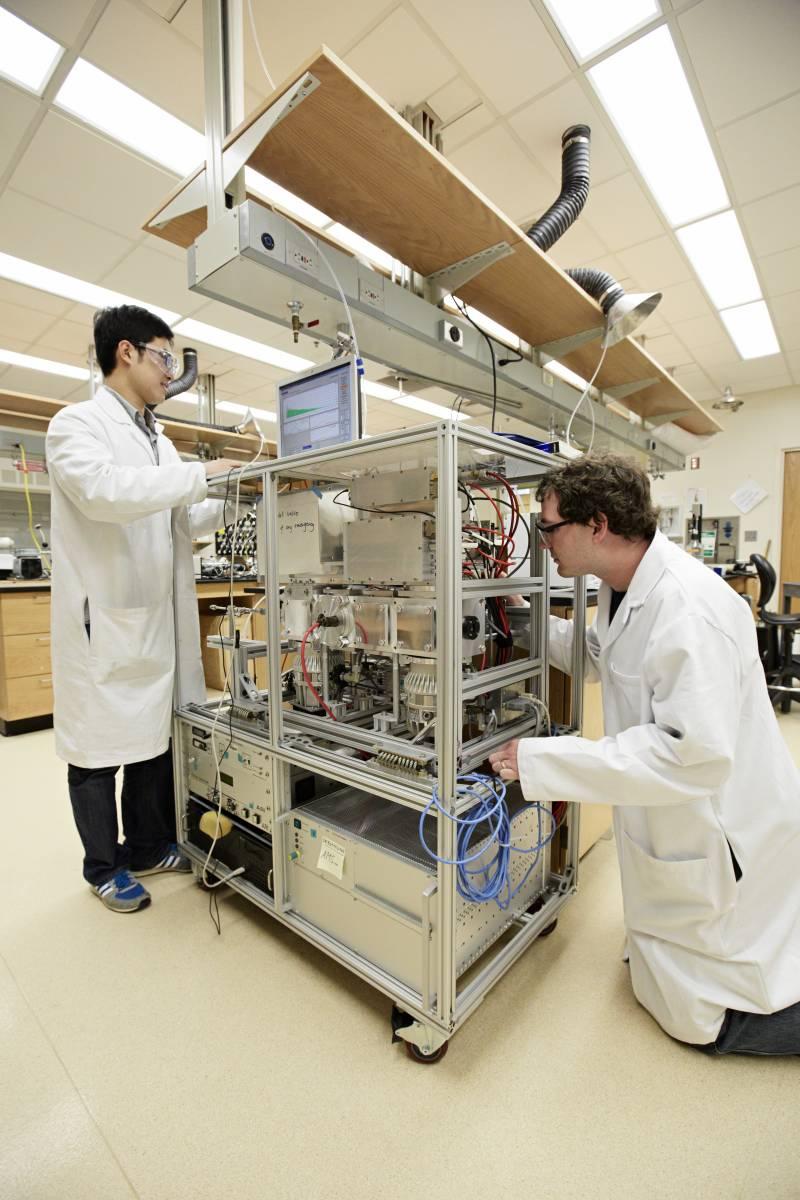

The High Resolution Time-of-Flight Aerosol Mass Spectrometer (HR-ToF-AMS) is the workhorse of the Ng lab. It can be deployed in the field to take ambient measurements, providing real-time characterizations of the chemical composition and the size of the aerosol particles at a given location. That data can then be used to recreate a location’s atmospheric conditions in the chamber facility, where repeatable experiments can be performed.

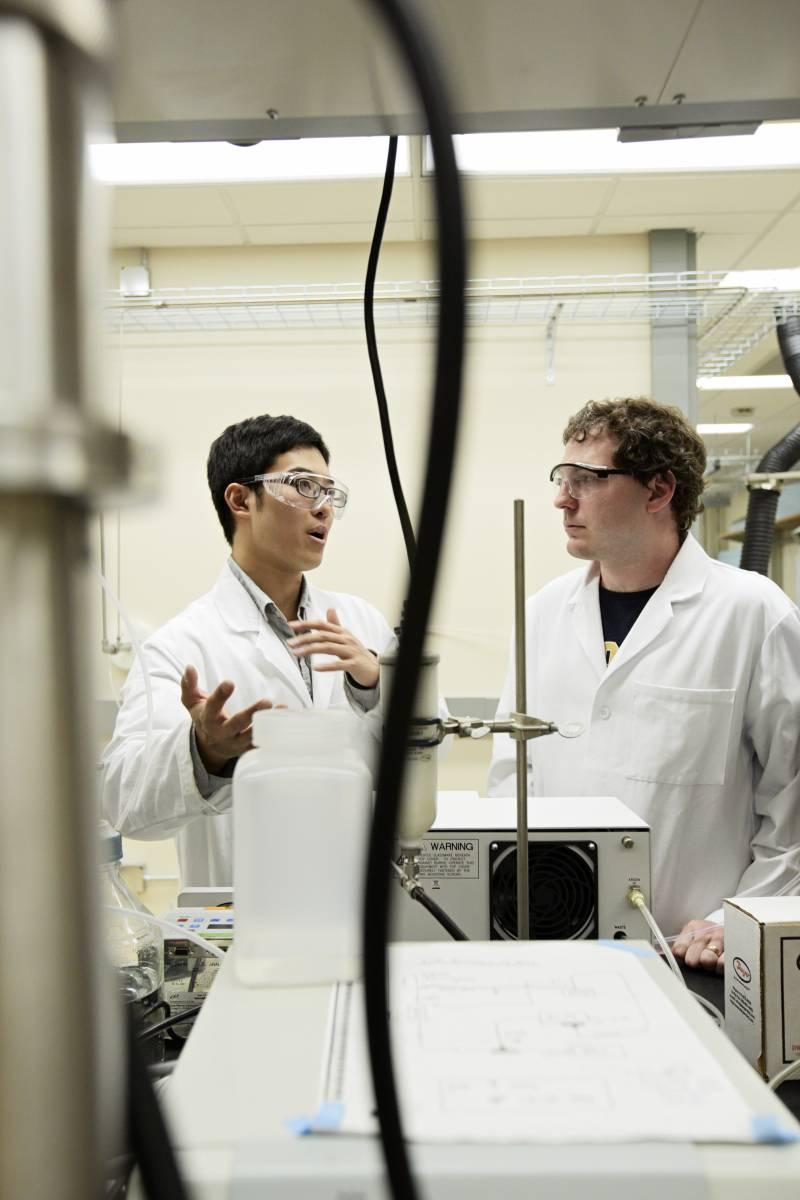

While a tremendous effort was made to make the two Teflon chambers as similar to each other as possible, they each have their own traits and characteristics. One of the first tasks for graduate students Christopher Boyd and Lu Xu is to calibrate the chambers so that the variations can be accounted for when conducting research. Like the rest of the facility, the injection system was designed and built to Ng’s specifications. It is used to fill the Teflon chambers with clean air made up of oxygen and nitrogen and, more importantly, free of particles and volatile compounds. The injection system includes a custom-built oil-less compressor system that was built on the roof of the Ford ES&T Building specifically for this lab. During the design and construction process Ng became an expert in component pricing, saving tens of thousands of dollars by shopping around for deals.

Xu and Boyd will have their hands full over the coming months as they conduct field analysis with the HR-ToF-AMS around Atlanta and North Georgia in conjunction with the Southeastern Center for Air Pollution and Epidemiology (SCAPE), a joint project with Emory University and the Environmental Protection Agency. With support from the National Science Foundation, they will also travel to Alabama to take samples as part of the Southern Oxidant and Aerosol Study, which includes more than 40 other institutions and organizations.

With her lab finally built, Ng is excited to delve into uncharted areas of research. “I lived the life of a general contractor for a year and a half, but in the end I think it was worth it. It was really built to my specification and it is exactly what I wanted. I’m very happy. I’m very grateful for the support of CoE and their faith in me to allow me to build this facility. We all share the vision that in order to do world-class science you need world-class facilities, and that is what we have built.”

Ed. note: This story appears in the first issue of Georgia Tech Engineers, the new magazine from the College of Engineering. To request a copy, please email the editor at editor@coe.gatech.edu