Specialized graduate programs demonstrate CoE’s agility in responding to industry needs.

Everybody, it seems, wants Ari Siesser. Young, intelligent and personable, Siesser says a week doesn’t go by without at least one corporate recruiter emailing him with a job opportunity.

That’s because Siesser (B.S. industrial engineering 2014, M.S. analytics 2015) has something that companies covet: the knowledge and skill to help predict the future.

“A lot of what I do can be used to predict the success of a marketing and advertising campaign,” says Siesser, who works for Atlanta-based business intelligence firm Cardlytics. “For example, we use credit card transaction data to evaluate how effective certain ads are in getting people to purchase products. We then use this information to identify which ads in the future will have greater purchase power.”

At 25, Siesser acquired his analytical wizardry through a highly specialized graduate program. The master’s degree in analytics blends the data modeling and statistical analysis expertise provided by the Stewart School of Industrial Systems & Engineering (ISyE) with the computational firepower of Georgia Tech’s College of Computing and the business analytics acumen from the Scheller College of Business.

While distinct, the program is actually one of several relatively new master’s degrees involving the College of Engineering that have a strong professional emphasis – two others being a master in supply chain engineering (SCE) and a master of biomedical innovation and development, or BioID. Together, the degrees demonstrate a remarkable level of agility from the nation’s largest engineering college, particularly in the ability to forge robust academic offerings that answer the fast-emerging needs of industry.

And “robust” is not an exaggeration. In a single year’s time, the programs immerse students in specialized knowledge, real-world projects and team-building experiences that exemplify the working world.

“Global supply chains are complex systems,” says Alan Erera, who directs the master’s in supply chain engineering program. “The ideas can be challenging to learn. But the training in statistical tools and operations research we provide helps students learn these powerful ideas and use them smartly to better plan and control supply chains.”

Over in the analytics program, the distinction begins with a customized mixing of courses from three top-ranked programs.

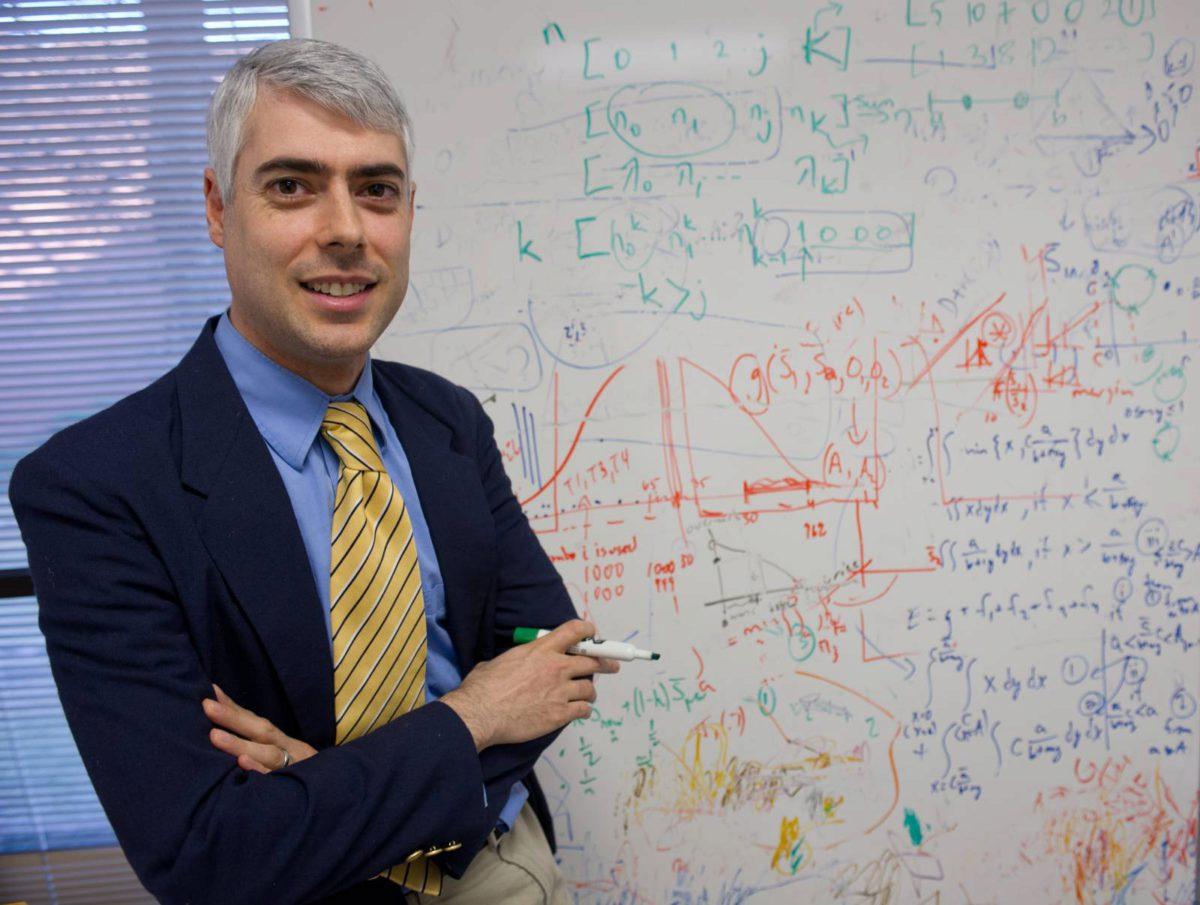

“Ours is truly a co-equal degree,” says Joel Sokol (left), who oversees the program. “ISyE is No. 1 in the nation and is particularly strong in statistics and operations research. The College of Computing has one of the best machine learning groups in the country. And Scheller is No. 5 in quantitative analysis.” He ties it all together to emphasize the point: “Only six universities in the U.S. are in the top 10 in industrial engineering, computing and business, and we’re the only one that has integrated all of these into a single degree.”

The three professional master’s programs share much in common besides their one-year time frame. Each enrolls highly diverse cohorts – different ages, nationalities and levels of work experience. And each gives students a unique, front-row view of industry through guest speakers, location tours and on-site project work (internships, practicum or capstone). The goal is to produce graduates who will be ready to perform on day one.

Rebecca Silver is one such graduate. An avowed supply chain enthusiast – “Whenever I order online, I like to see how long it takes for the order to change to ‘ship’ status” – Silver graduated from the M.S. in supply chain engineering program in 2014 and immediately went to work for Nike. Her job was to improve the inner workings of the company’s only U.S. distribution center for shoes. In early 2015, when Nike moved to a gargantuan facility of 3 million square feet – where all footwear, apparel and equipment would be shipped, usually within 24 hours of ordering – Silver’s role in Nike logistics expanded.

“When it came online, the new building had 31 miles of conveyer belts,” Silver says. “It also required a new warehouse management system and processes. There was a lot to test and a lot of places where things can go wrong.”

Originally assigned to the engineering team over one area of the center, Silver is now on the planning team to optimize order processing and shipping for the entire building. She credits her Georgia Tech graduate education for her rapid rise at Nike.

“The program gave me the ability to work on teams, think analytically and know how to ask the right questions,” she says. As an example, she cites her capstone project for Pacific Star, a Mexico City-based food supplier to KFC, Pizza Hut and other restaurant brands. Silver and her three project teammates examined vast amounts of data provided by the company, then flew to Mexico to study operations.

“There were a lot of refrigerated and frozen products, so of course everything has an expiration date,” she says. “Our team recommended how they could improve several processes – how they place orders, load trucks and ship products without spoiling. We actually got to see some of the recommendations incorporated while we were there.”

Sathya Gourisankar describes similar real-world projects that have emerged from the BioID program, which he directs. “One group worked on a novel method to reduce pain during urethral procedures – they came up with an extraordinarily clever and innovative design for a urethral stent,” he says. “They created and tested a prototype. The performance was so promising, their clinical mentor, who was a urologist, said the product would be a great benefit to his practice. That was a huge compliment.”

The connection works the other way, too – students already in their careers bring a professional perspective to the professional degree programs. Having worked for 18 years in the financial and technology industries, Ankur Garg came to the M.S. in analytics program after seeing how the data landscape was changing in the corporate world. He was struck by the ways in which the analytics degree could be customized based on each student’s interests.

“We have the ability to choose one of three separate tracks,” he says, referring to the analytical tools of ISyE, the business analytics of Scheller and computational analytics of the College of Computing. “The blend itself is really unique, and the number of electives is very large.”

No matter which combination of courses graduate students take as they pursue their degree, those working toward the M.S. in analytics will be attractive to prospective employers. Big data is becoming an increasingly big factor in corporate decision-making.

“Some companies are pretty advanced in analytics, while others are happy to get the basics up and running,” says Katherine McKenna, who will complete the program this summer. “But it’s challenging to keep up with new algorithms and technologies, which is why there’s such a big demand for people.”

Likewise, the BioID program produces graduates who are day-one ready to work in the expanding medical device industry. “Companies invest a lot of time training employees,” says Gourisankar, who spent three decades in the medical device industry before Georgia Tech hired him. “That’s why they brought an industry insider like me to run the program – to bring real-world practices to the classroom. We also have a team of big-gun medical device people, so the students get mega world exposure through the program.”

Lance Black is one such student. A practicing physician in the U.S. Air Force and biological engineering graduate from Louisiana State, he recounts how he pivoted from medicine to medical devices. “Being an engineer ruined me for being a physician,” he says, laughing. “Shortly after I started treating patients, I realized this wasn’t what I wanted to do the next 25 years. There aren’t a lot of creative outlets in practicing medicine. You’re not making things up as you go along, because you really shouldn’t be.”

A consultant with the Global Center for Medical Innovation (GCMI), billed as “the Southeast’s first and only comprehensive medical device innovation center,” Black says the center director encouraged him to apply to the BioID program. He did and found the yearlong program “a safe environment to think outside the box.” After graduation, GCMI hired Black full-time as its medical affairs manager, helping entrepreneurial physicians who seek to develop medical devices.

“I’ll spend hours in the office brainstorming ideas, working through different iterations, doing risk assessment,” he says. It’s an experience that perfectly blends his engineering and medical backgrounds, and Black credits the BioID program for helping him achieve his larger goal of contributing to the growth and development of an industry.

In a similar way, graduates of the M.S. in SCE program are evolving the supply chain industry by optimizing the supply chain, a critical goal for companies searching for new ways to serve their customers better. Georgia Tech ISyE master’s students in supply chain engineering have an edge compared to students in traditional supply chain management programs – rather than simply plan activity in the supply chain, they engineer solutions to optimize it at any point.

“The best thing I learned is being open to how to solve a problem,” says Subhash Segoreti (M.S. SCE ’15), who is now working to optimize the European supply chain for Cisco. “Beyond the hard skills, I learned about working with different cultures and being adaptable. At Georgia Tech, you learn the skills that are very important.”

- - - - -

At the crossroads of supply chain activityAs elevator speeches go, Tim Brown’s take on where Georgia stands in supply chain and logistics is impressive:

Atlanta was founded as Terminus, based on logistics, with two rail lines coming together. When mail distribution moved to the air, Atlanta was chosen over Birmingham as an airport hub. Since then, Hartsfield-Jackson has grown to one of the busiest airports in the world. Savannah is now the nation’s second largest container port. Brunswick is No. 1 in auto imports. Atlanta is one of just two U.S. cities that have three interstates intersecting through it. Georgia is home to two intermodal yards in its ports, two more in Atlanta. It’s also the headquarters of global supply chain retailers – Coca-Cola, Newell Rubbermaid, Home Depot, others – and of course, UPS.

Small wonder that Georgia Tech has chosen to become a major partner to the industry, not only through the College of Engineering’s graduate program, but also through an Interdisciplinary Research Center (IRC) for Supply Chain & Logistics, for which Brown serves as managing director.

One of seven such centers on campus, the IRC unites supply chain programs and professionals across Georgia Tech in research, education and outreach. Among other activities, the center:

o pursues major grants for multi-disciplinary research in transportation, logistics and other areas;

o orchestrates professional development courses for people in the industry and provides course content; and

o coordinates industry projects for more than 2,000 Georgia Tech students, including capstone experiences for graduate students.

The IRC also houses the new “Physical Internet Center,” an endeavor working to apply the fundamentals of the Internet – speed, standardization, interconnectedness – to the operation of logistics and supply chain systems.