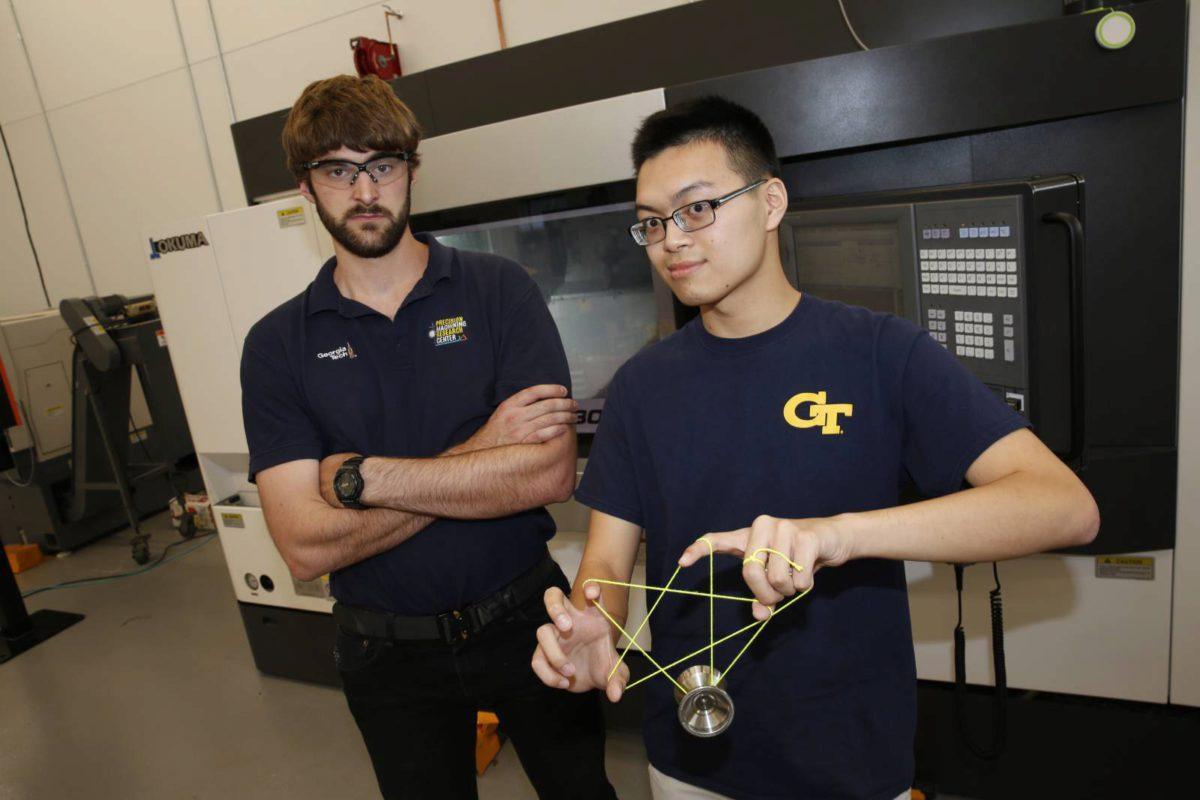

Yoyo champ and grad student team up on unique project

He can walk the dog, shoot the moon, or go around the corner. This engineer has an unusual hobby.

Meet Darren Tan, a three-time state of Georgia yoyo champion. Fascinated with yoyos as a kid in Malaysia, he didn’t get serious about them until the start high school in Cobb County. Tan has competed at state and regional levels for the last four years, where he has had great success. It’s a creative sport, and Tan enjoys the combination of aesthetics and technicality.

“In Malaysia, there were TV shows about yoyos,” said Tan. “One day I went to the mall and saw a group doing a yoyo demonstration. I just thought that was the coolest thing, and I got my first yoyo. Back then, I didn't have much of an attention span, so I didn't keep up with it. At the end of eighth grade, I needed something to do for the summer, and I walked into a toy store and found a yoyo. I tried it out for nostalgia's sake, and I've been doing it ever since in my free time.”

At the same time Tan was training and competing, Tech was offering a class on design, manufacturing and implementation (ME 2110). Roby Lynn, mechanical engineering Ph.D. candidate, works under Tom Kurfess, professor and HUSCO/Ramirez Distinguished Chair in the George W. Woodruff School of Mechanical Engineering, helping manage the Kurfess lab and teaching ME 2110, Creative Decisions and Design. The class focuses on mechanical design and manufacturing, and teaches students to use computer-controlled (CNC) equipment. When the time came to choose an item for students to design and build, Lynn and Kurfess settled on something fun that most students would have a passing familiarity with – a yoyo. With the yoyo design and build, students learn how to use the machines and computer-aided manufacturing software.

Video by Candler Hobbs, Woodruff School of Mechanical Engineering

When Tan heard from a staff member that his fellow mechanical engineering majors were making yoyos in class, he wanted in on it. Rather than waiting to take ME 2110, he spent several weeks this summer working with Lynn on a new design that eventually resulted in the production of several high-quality titanium yoyos.

“Coming into Tech, I didn't really know what I wanted to major in,” said Tan. “Since I knew something about CAD and machining, I thought I'd jump into mechanical engineering. I didn't expect to be making my own yoyo. It's really cool to be able to apply what I'm doing as a hobby to my academic work.”

One of the challenges for Lynn was making the design and manufacturing process as streamlined and efficient as possible. The yoyo consists of two identical pieces machined out of a solid rod of titanium, and the tool path must be optimized for efficiency to avoid wasting time and materials.

“We developed this software to make tool paths for the different machines we have at our disposal, and we're learning that current generation CNC machines are not really sufficient for very high complexity machining projects,” said Lynn, who explained that the yoyo design involves steep angles, as well as intricate threading that connects the two halves. “Now we're looking at developing new machines.”

In order for the yoyo to balance properly, both halves had to be identical, so getting the process right and replicating it was very important for Lynn and Tan. Working with Lynn to make the yoyo gave Tan a leg up before he takes ME 2110 later this year.

“Design is really iterative,” said Tan. ”You're not going to get it right the first time. For example, we had edges that were too sharp, and they cut the yoyo string. You have to keep refining, see what goes wrong, fix it, and then see what else goes wrong.”

With the bugs worked out, Tan will have the chance to take his custom-built yoyo inscribed with his college’s name on it with him to competitions and show that at Georgia Tech, you really can build just about anything.