As the drive to invent new materials shifts into high gear, the view of tomorrow is inspiring

The world we imagine tomorrow sometimes seems locked in a dream. In this world, the oceans are free of plastic, the skies cleared of carbon. Our kitchen counters can fend off germs. We pack the electric car for vacation, knowing we can travel farther without recharging. As we age, implanted medical devices are embraced by our bodies, happily integrated into tissue and bone.

Such a world remains in the distance, but it’s coming into view much quicker, thanks to the collective, collaborative minds of researchers in materials science and engineering (MSE). So much of what we see around us – the physical matter of everyday life – will change because the field itself is evolving. What was once a trial-and-error realm of pure experimentation has opened up, ushering in a new era of accelerated discovery.

The fuel for this progress is a convergence of technology, method and information. Sophisticated new instruments are being developed, allowing engineers to delve deeper into materials. Experimental approaches are maturing as some researchers dedicate their work to refining processes. And computational science and data analytics are speeding everything that’s observed and learned, present and past, to shape new understanding.

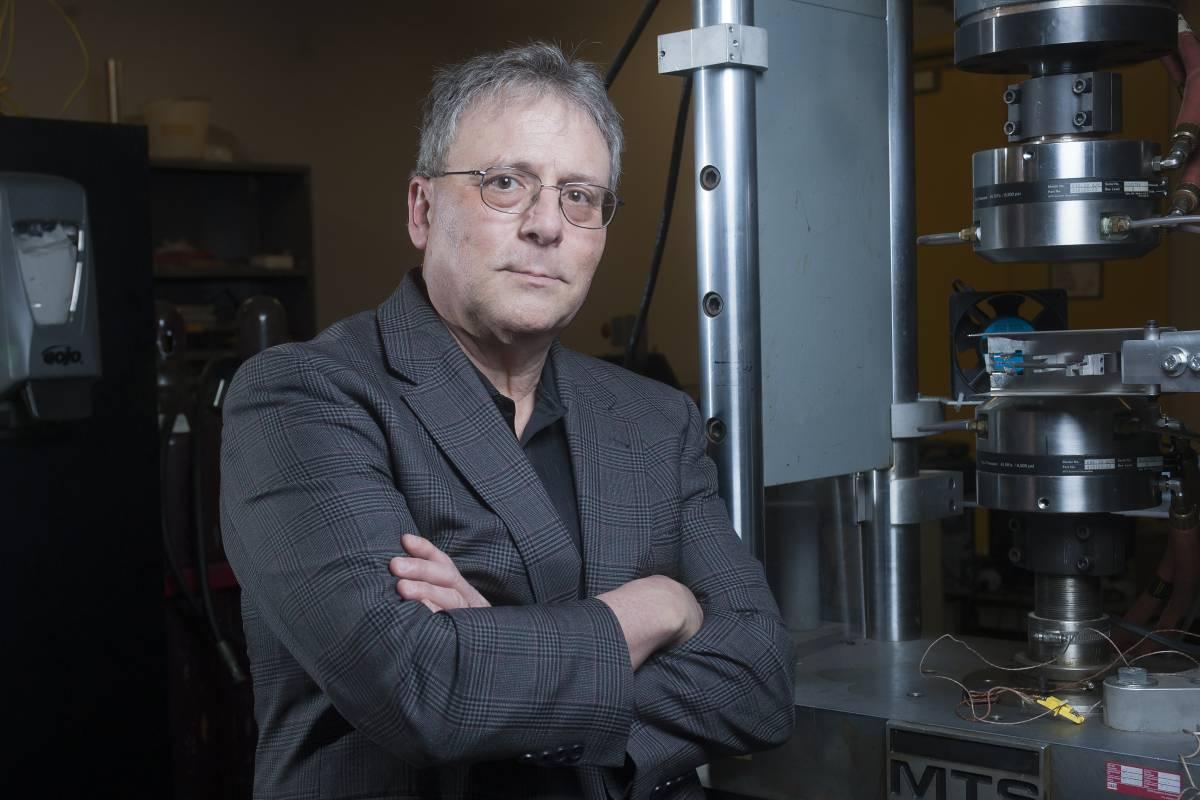

“By 2030, a lot of our initial thinking about what materials design looks like will have changed,” says Dave McDowell, a professor with dual appointments in mechanical engineering and MSE. “It’ll be replaced by autonomous, smart systems that have artificial intelligence engines working in the background. These systems will incorporate experimental data, simulation and expert knowledge, all to reduce uncertainty.”

McDowell has been at this for 37 years inside Georgia Tech’s College of Engineering. In the early days, he conducted stepping-stone experiments like everyone else. But in the 1990s, he saw the potential of using computer science to extract more insight out of those experiments.

“And then came what I call the ‘democratization’ of quantum mechanics,” he says. How subatomic particles moved and interacted could now be better understood by a wider range of investigators, opening up a trove of new principles and theories for MSE researchers to explore. The discipline was morphing into something more predictive, thanks to a fusion of experiments, computation and data science.

“There’s probably 10 universities in the U.S. today best known for excelling in this convergence,” McDowell says, “and we’re one of them.”

One superstar in the computational field came to the College of Engineering in 2017. His name is Rampi Ramprasad, Michael E. Tennenbaum Family Chair and a GRA Eminent Scholar who melds quantum mechanics with computer models to propose hypothetical new substances. The approach allows him to evaluate hundreds of potential materials, the most promising of which can be chosen for further experimentation.

By leveraging computing and data science, Ramprasad develops new tools for researchers to create or modify materials. The beauty of such tools is that they help engineers imagine what could be – or, in the case of Matt McDowell, to see what really is.

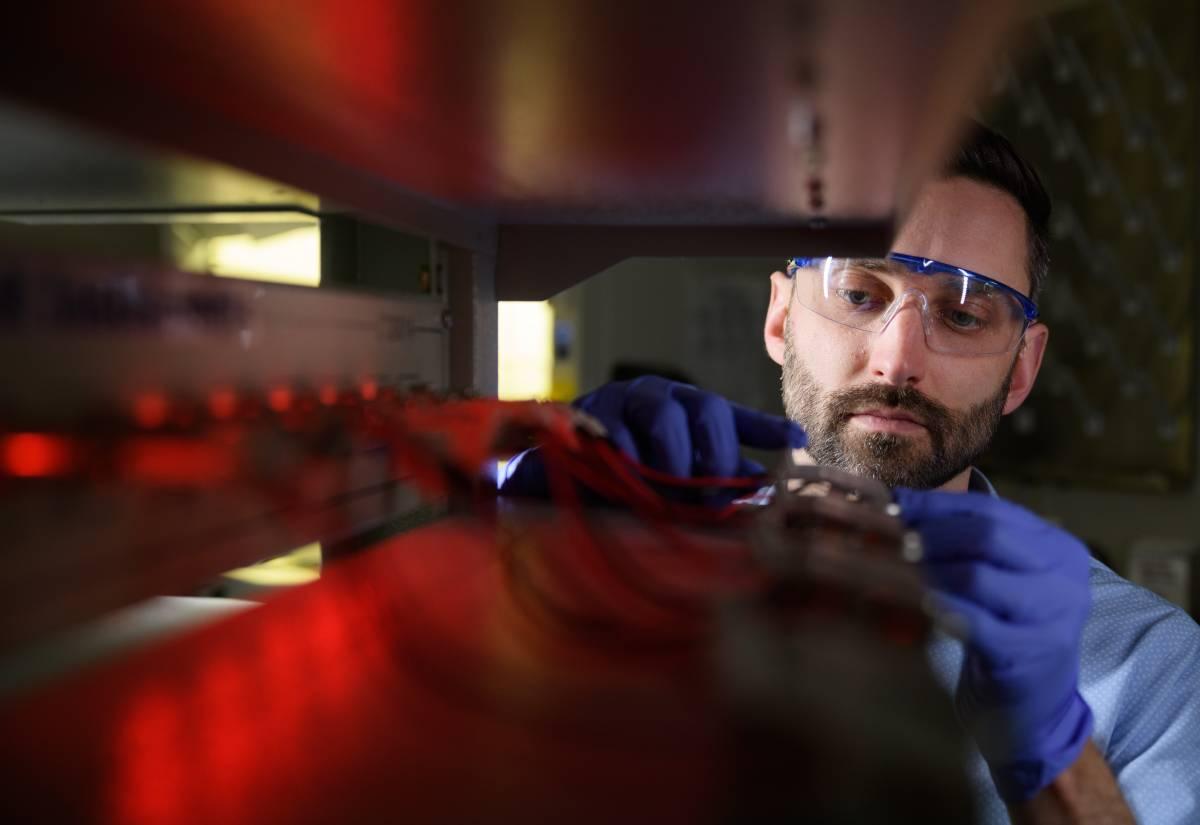

Matt McDowell is an assistant professor in MSE and mechanical engineering and, so it happens, the son of Dave McDowell, Carter N. Paden Jr. Distinguished Chair in Metals Processing in the Woodruff School of Mechanical Engineering. His specialty is in situ experimentation, which allows him to witness what happens to a material – all the way down to the atomic level – as different kinds of stimuli are applied.

Batteries are a big part of McDowell’s work. The refinement of lithium-ion batteries over the past decade has ushered in a new era of charging capacity. The next step is to develop new materials that can make them last longer – no small feat, as evidenced by McDowell’s work.

In one set of experiments, he designs a battery that allows it to be inserted into a synchrotron, a massive circular machine with a diameter bigger than a football field. “We bombard the battery with X-rays and get a three-dimensional view of what’s happening to the material inside that battery, over time,” McDowell says.

Though less than a centimeter in width, that view of the battery is considered large scale, and his experiment yields so many terabytes of data, a single hard drive can’t hold it all. Yet for McDowell, that’s only half a look. Using different instruments, he also studies what happens when he assails the same material with electrons. The product of that effort is a 2D video of what’s occurring at the atomic level as the battery charges and discharges.

“Developing new materials can either improve the batteries we have now or bring an entirely new energy storage system,” McDowell says. “Our lab is using in situ experiments for both purposes.” McDowell thinks we’re only a few years away from a battery that lasts 20% longer, thanks to new materials inside existing cells. Beyond that, an entirely new platform like solid-state batteries could bring 50% longer storage.

Such a battery would change the world, and not just because you’d need to charge your phone less often. It would make electric vehicles far more commonplace because they’d travel much further. Beyond that: In your lifetime, you just might be able board an aircraft that has numerous battery-powered engines, rather than a few gas-turbine ones.

Pushing the engineering envelope

As MSE research gains momentum, new answers to problems enter the picture, and the College of Engineering is doing its part. There’s Mark Losego assistant professor of MSE, and Shannon Yee, associate professor of mechanical engineering; together, they’ve developed an alternative to pressure-treated wood. By employing the atomic-layer deposition methods used to manufacture semiconductors, the two have developed a way to permeate the cells of wood with a few atomic layers of material. This makes the wood more water-resistant than the pressure-treated variety and brings the added benefit of reducing heat loss in homes.

There’s Craig Green (Ph.D. ME, ’12), the CTO of Carbice, a Georgia Tech startup. The company has engineered a kind of “wonder tape” that, when integrated into electronics, dissipates heat, a huge problem as electronics become more powerful. Forged from carbon nanotubes, the thermal material is already being used in space satellites.

There’s Mark Prausnitz, Regents' Professor and J. Erskine Love Jr. Chair in Chemical & Biomolecular Engineering and a pioneer in microneedle technology. His latest invention is called STAR particles. The materials hold infinitesimally small needles that contain medication, and when rubbed into the skin as a cream, the particles promise to improve treatment of skin diseases.

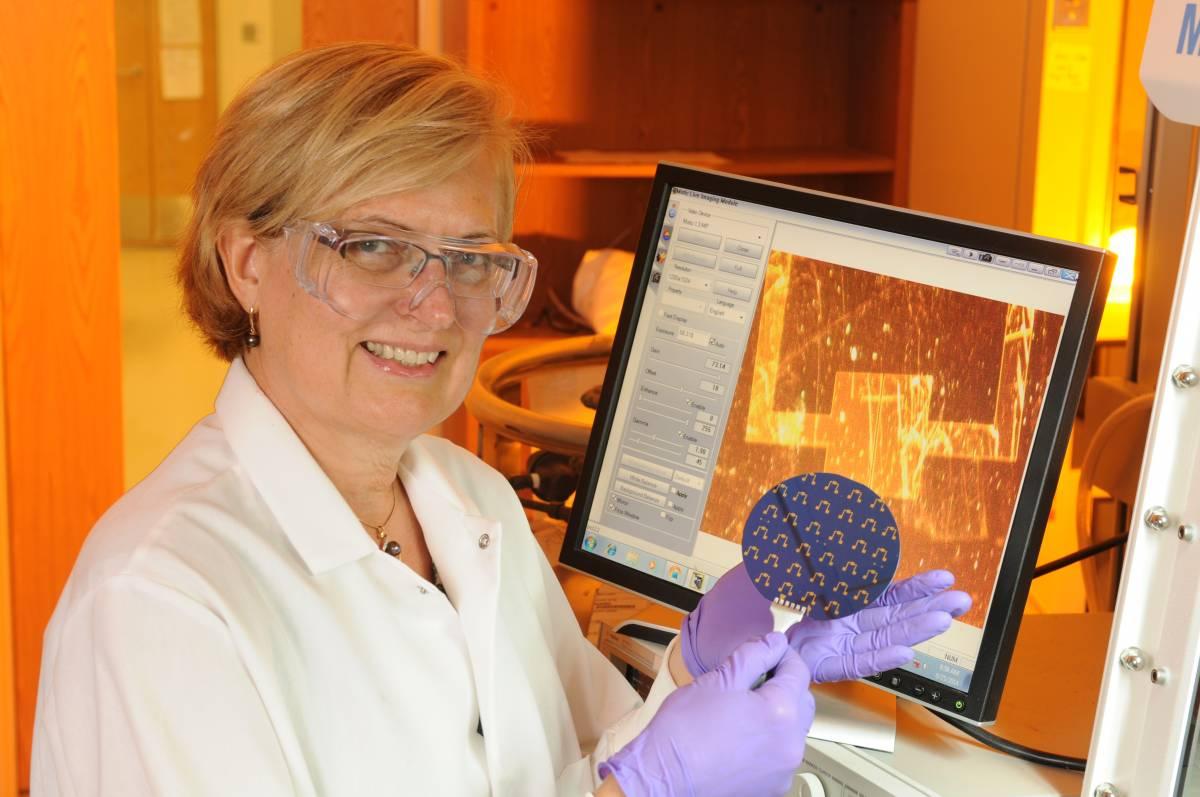

And there’s Elsa Reichmanis. An accomplished researcher from Bell Labs and a professor in the School of Chemical and Biomolecular Engineering – her work, among other things, led to new families of lithographic materials that advanced semiconductor design – she has a rare vantage point from which to view the future.

Last year, Reichmanis joined some of the nation’s most accomplished materials experts on a National Academies of Science, Engineering, and Medicine super-committee to study what the decade ahead will bring. It was an exhaustive effort, delving into metals and alloys, ceramics and composites, two-dimensional materials and meta-elements.

“A lot of new things will be coming out,” Reichmanis says. “I believe we’ll have truly biodegradable packaging materials. We’re not going to be throwing out all this plastic. I think we’re going to have manufacturing processes where we’re not emitting the amount of greenhouse gases we are now. We’ll have even more renewable energy sources – there are tons of opportunities there.”

What will it take to get there? Reichmanis maintains that the best investment is in efforts that assure a growth of mindpower.

“More smart people attacking major problems could speed things up,” she says. “We have to make sure the field remains interesting for students who choose to further their education. That requires changing how we present the information to students, not just so they understand it, but so they say, ‘Aha! This is really interesting. I want to be doing this.’”

Which is to say, the pull of complexity and the push of acceleration demand a greater diversity of innovators and ideas. If the future is a contest of minds versus matter, it’s essential that the minds win.