Engineering students 3D print PPE for their families on the front lines, including masks and no-touch door openers

It all started with a call from his family in California. They were manufacturing 3D-printed masks for Covid-19 first responders and asked their cousin Suyash Rajesh, a rising third-year mechanical engineering student from Georgia, to start doing the same for their family in Atlanta.

“My mom works in a dialysis clinic, and my cousins, aunts and uncles are all doctors, so it hit very close to home,” said Rajesh. “They are working all the time, and I’m very concerned for their wellbeing, so I thought I could help out in some way.”

A similar situation presented itself to Kian Zarbaf, a rising second-year aerospace engineering student from Miami. His cousin works in Mobile, Alabama in the ICU, and his aunt is a nurse in Miami. Zarbaf had heard of a no-touch door opener and wanted to start 3D printing them for his family members and their colleagues to use in the hospital.

“I had seen no-touch door openers being sold online for $30, which seemed outrageous in a time when people are doing everything they can to stay safe,” said Zarbaf. “But with my 3D printer, they cost less than 30 cents to print from plastic.”

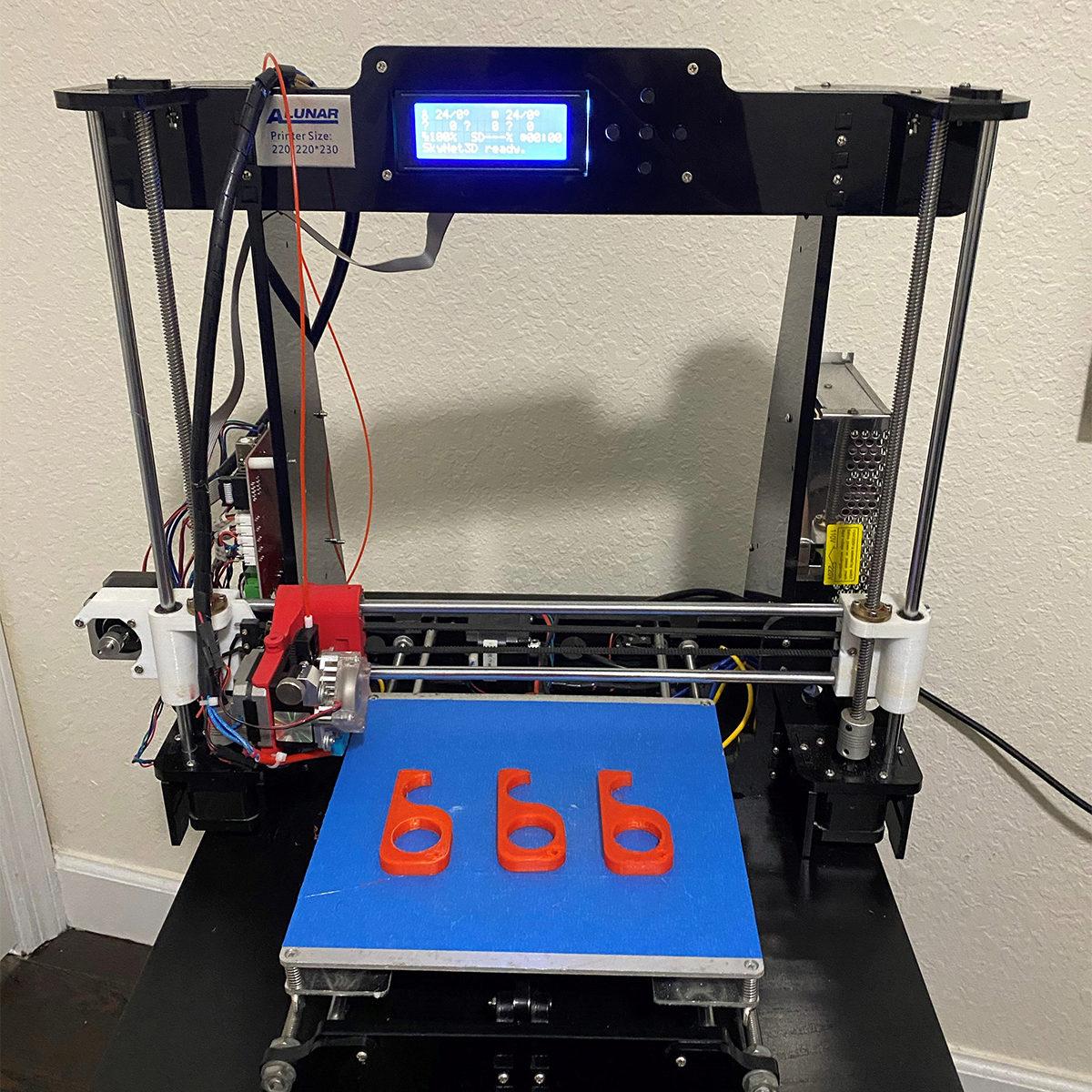

Zarbaf designed his own version of the no-touch door opener in CAD (computer aided design), making tweaks and upgrades along the way until he had perfected a door opener that was comfortable for a persons finger and gave plenty of leverage to open a heavy door. It functions as a button pusher as well – or for other highly trafficked areas that need to be touched. He says the door opener is also for anyone going about their daily errands that want to feel safer about going to the gas station or grocery store.

Rajesh also created a no-touch door opener for his family and their medical colleagues to use. He found an open sourced version of the door opener and started printing. He’s up to 40 now and giving them to anyone who wants one. Rajesh also turned his efforts towards masks. He’s 3D printed masks for all his family members that work in the healthcare industry and packages them up with extra filters and straps, as they are reusable.

Rajesh bought his 3D printer specifically to help with Covid-19 efforts. He’s spent countless hours tweaking and improving the printer to make higher quality PPE, going as far as opening up the circuit board and adding diodes to make the signal that goes into the 3D printer smoother. He’s been interchanging parts as well to figure out how to engineer the best quality masks.

Another device Rajesh is printing is a mask stretcher that takes pressure off the backs of the ears, so healthcare workers are more comfortable. He can easily print five of those in 30 minutes and has been donating them to the community.

“Creating these tools has showed me that anyone can have an impact, and that you don’t have to be large and expansive to reach your community,” said Rajesh. “You can still do small things and have a positive effect. It’s cool we can use technology like 3D printing to help with the pandemic because I wouldn’t have believed that before.”

Zarbaf feels the same way.

“I felt like the no touch door opener was such a simple tool I could create and contribute, but it could make a big difference in helping people feel safe,” he said.

Both Rajesh and Zarbaf are Clark Scholars at Georgia Tech, a needs-based scholarship that pays for all four years of college. One of the core pillars of being a Clark Scholar is giving back to the community. Both students feel like their efforts to combat the spread of Covid-19 align well with the mission of a Clark Scholar.

“One of the main appeals of the Clark Scholars program for me was community service,” said Rajesh. “I really wanted to give back. Before the pandemic, I wasn’t able to give back in a way that was unique to me. But now I feel like I am really putting my engineering skills to use for good and giving back to the community.”

“I knew that what I was doing could really help people,” said Zarbaf. “I’ve had a 3D printer for so long, and I’m so familiar with it that it was easy for me to manufacture these devices and play a small part in keeping people safe from Covid-19. Contributing like this ties into what being a Clark Scholar is all about.”

Next steps for both Rajesh and Zarbaf include wide dissemination of the PPE and no-touch door openers to local hospitals and medical centers. Zarbaf also wants to start manufacturing face shields.

“I know there are a lot of open source files for face shields, and I could easily print the plastic parts,” he said. “So, I might go in that direction next to continue contributing to fighting Covid-19. I’ll also be working with my cousin in Alabama about the needs of her hospital, as well as local hospitals in the Miami area.”

Rajesh hopes to widen his reach with his 3D printed PPE and is taking inspiration from others at Tech.

“I was inspired by Dr. Saldana’s work [a mechanical engineering professor at Georgia Tech],” said Rajesh. “His efforts prompted me to reach out and use what I’m learning and the skills I have to make a difference no matter how small it is. Dr. Saldana’s team continues to donate PPE, and I'm hoping to follow that example going forward with reaching out to other organizations.”