Stretching across three colleges, TechMade unifies design experiences across campus along with fellowships for grad students and a new undergrad course.

(text and background only visible when logged in)

A new initiative across the colleges of engineering, business, and design will give Georgia Tech students hands-on exposure to the full sweep of product realization, from design to manufacturing, no matter their major.

Dubbed TechMade, the goal is to unify the widespread design and creation opportunities on campus and add new facets while building a collaborative design community for graduate students and researchers across the Institute.

The initiative kicks off this fall with a new undergraduate course crafted for third-year students in the three colleges. TechMade will also select inaugural fellows, a cohort of four graduate students who will help seed a research community focused on design.

TechMade is the brainchild of the George W. Woodruff School of Mechanical Engineering’s Devesh Ranjan and is being built by Woodruff Professor Carolyn Seepersad, Wayne Li in industrial design, and Karthik Ramachandran in business.

“TechMade will be an opportunity in the long term to give any Georgia Tech student exposure to hands-on designing, building, making, and product realization in a meaningful way,” said Seepersad, who joined the Woodruff School last year to begin realizing the TechMade vision. “We don’t want to create something that just serves engineers or just serves industrial designers. We want something that serves all students across the Institute.”

TechMade is organized around three pillars: making and manufacturing, human-centered design, and what the team called “digital engineering” — teaching students to use the newest technology, like artificial intelligence, alongside their human skills to design and realize products.

Seepersad said TechMade isn’t about adding on to existing programs and opportunities, The goal is to unify the disparate offerings that already give students design experience, weave them together, and create additional pieces to strengthen students’ backgrounds. Well-known programs like Capstone Expo and the Flowers Invention Studio will be integrated under the TechMade umbrella alongside the new course for undergraduates, the graduate TechMade Fellows, and a research symposium series.

Li said a formalized ecosystem of product realization education responds to students’ desires for even more opportunity in this area.

“There is a hunger to complement theory with practical understanding of engineering concepts applied in real world situations,” said Li, professor of the practice for design and engineering in the School of Industrial Design.

Ranjan said TechMade taps the technological resources available across Georgia Tech to provide a unique, transformative experience for students, no matter their aspirations or degree program.

“Tackling problems of global significance requires creative, interdisciplinary solutions, and TechMade will be a platform for helping our students think outside the box,” said Ranjan, Eugene C. Gwaltney Jr. School Chair of ME. “It will act as a hub for enhancing transdisciplinary activities between different colleges and create a new educational experience in design for our students.”

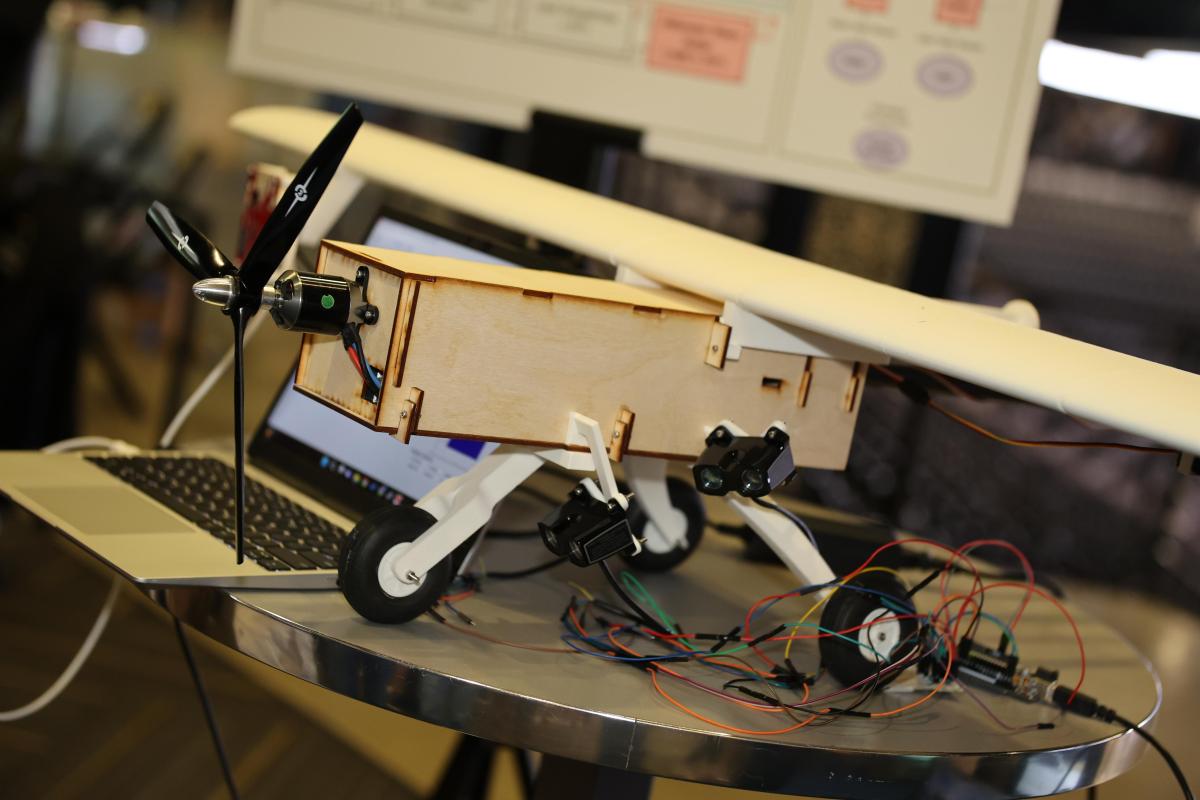

The TechMade initiative complements existing design opportunities and curriculum at Georgia Tech, including the Flowers Invention Studio (top), Capstone Design Expo, and the second-year design course in mechanical engineering (bottom). Rather than add on to these offerings, TechMade is intended to unify the disparate design experiences for students, weave them together, and create additional pieces to strengthen students' design backgrounds. Capstone Expo and the Flowers Invention Studio will be integrated under the TechMade umbrella alongside a new product realization course for undergraduates, graduate student TechMade Fellows, and a research symposium series.

Hunger for Design

Georgia Tech engineering students already learn about design in their educational journey. And that’s true for other majors, too. TechMade will expand that design education — deepening it for students in disciplines where it’s a focal point and offering the full picture of product realization for majors where it’s less common.

“An engineering background helps students understand certain aspects of product design and realization, but a business student’s background helps them understand other things better. And someone from the sciences or someone from design will understand other facets better,” Seepersad said. “There’s more opportunity to meet the students where they are and help them have this experience in product realization and what it means to transition an idea into reality.”

(text and background only visible when logged in)

(text and background only visible when logged in)

The Inaugural TechMade Fellows

One focus of the TechMade initiative is to have a bigger impact on graduate students. Each year, a small group of graduate students will be TechMade Fellows, They will receive a year of financial support and serve as the nexus of a monthly research symposium series for design-focused research. TechMade Fellows also will be charged with helping to build community across the pockets of design throughout campus. Meet the first Fellows:

Taylor Allen

Ph.D. student, Mechanical Engineering

Allen’s doctoral research focuses on optimizing assistive technology design — work driven by a desire to design and fabricate products to make life easier for people with disabilities.

“Many assistive technology products never make it to market. And if they do, the rate of abandonment is very high. Design and commercialization barriers, including the breadth of functional diversity of individuals with disabilities and a very small market size, preclude inventors from developing robust, affordable products. I’m trying to remove some of those barriers.”

Madison Hales

Ph.D. student, Robotics

Hales studies the roots of rice plants to understand how they respond to environmental stimuli and grow in the soil. Her hope is that the strategies plants use to move and grow in a complex medium like soil can inform designs for robots that are able to operate in highly unstructured environments.

Hales has developed an apparatus to study the roots’ growth in response to gravity. Support from the TechMade Fellowship will help her expand her approach to other sensory pathways, like light, touch, and temperature.

“The thing I appreciate most about this work is how it uses a variety of techniques from different fields — botany, engineering, physics, etc. — to develop ideas that couldn’t be achieved when studying plants from any singular lens. I also appreciate how much it has allowed me to develop a wide breadth of valuable skills and knowledge across disciplinary barriers.”

Mahsa Hedayati

Ph.D. student, Architecture

Hedayati’s research focuses on developing a machine learning model to provide accurate, individualized thermal comfort predictions for building occupants. The model will consider environmental, physiological, psychological, and cultural factors with the goal of enhancing comfort while significantly reducing energy consumption in buildings. Her study also involves evaluating the effectiveness of personal comfort systems — for example, heated or cooled chairs — which allow individuals to control their immediate environments.

“This work is crucial to me because it addresses the urgent goal of achieving net-zero carbon emissions by 2050, which is vital to prevent the most severe consequence of climate change. Buildings account for 42% of global CO2 emissions.”

Jamila Khanfri

Ph.D. student, Mechanical Engineering

Khanfri is studying 3D printing processes for metals in hopes of standardizing and automating an emerging and promising technique.

“There is an ever-expanding demand for new materials and manufacturing capabilities. For example, space exploration requires materials that can withstand higher temperatures, and advanced medical devices require more precise and fragile geometries. This project intrigues me because it is at the forefront of these material and manufacturing advances.”

(text and background only visible when logged in)

One way Seeparsad, Li, and Ramachandran have worked to deepen the experience for students is a new course debuting for the Fall 2024 semester called Product Design and Realization.

Aimed at third-year students, the class of around 30 will mix mechanical engineering, business, and industrial design students, mirroring the way product teams work in the real world. The course will be organized around the three TechMade pillars.

Interdisciplinary teams will work all semester on a big project while, along the way, solo assignments will dive deeper into making and manufacturing, human-centered design, and digital engineering. That will mean tapping low-cost, accessible tools in makerspaces and perhaps more advanced capabilities in spaces like the Advanced Manufacturing Pilot Facility. Students will learn about AI and machine learning tools to aid in design or mine user data and preferences — marrying human skills with algorithmic power to reach the right process or product.

None of that means business or design students have to understand complex engineering calculations or modeling, for example. The goal is for them to be able to understand those things well enough to work with their engineering teammates to improve the process or product.

“I am a big believer in higher education as an empowerment exercise, rather than just sharing knowhow,” said Ramachandran, Dunn Family Professor in the Scheller College of Business. “Whether our students are talking to a future employer, a potential consumer, or an investor about their creative ideas, it is useful to remember the old mantra: Show, don’t tell. A formal course that introduces design and manufacturing knowhow to our students will be massive in empowering them.”

Growing the TechMade Ecosystem

In these early days, TechMade is a collaboration across engineering, design, and business, but Seepersad said the aim is to involve the other Colleges on campus and expand to the entrepreneurial ecosystem in Atlanta.

Already, the TechMade Fellows span a variety of fields, and the design community they’re seeding will be agnostic of discipline. More sections of the Product Design and Realization course could come online in future years, too, including any School interested in integrating more product realization into its elective offerings.

Seepersad, Li, and Ramachandran are thinking about how to build modules and tools to make it easy for other instructors to pick up the course and teach it.

Philanthropic support will be a critical factor for the growth and sustainability of the TechMade vision, Ranjan said: “The TechMade initiative will have a transformative impact on Georgia Tech students, enabling these future engineers and designers to produce novel ideas and create solutions to the world’s most challenging problems.”

Team Big Bird Wins Top Prize at Summer Capstone Mini-Expo

The team of ME and MSE students focused on improving Safran Test Cells' Big Bird transporter, which helps customers move their test cell engines from one location to another.

Capstone Design

Capstone Design is a culminating course offered to undergraduate students in most engineering disciplines. Students work in teams to design, build, and test prototypes with real world applications. At the end of each semester, students showcase their efforts at the Capstone Design Expo.

Flowers Invention Studio

The Invention Studio is a student-run makerspace open to the entire Georgia Tech community. Students are encouraged to “own” the space. Prototyping Instructors, or PIs, lead other students in the use and maintenance of the space, ensuring that the resources remain available to those who wish to use them. We promote an ethic of responsibility, safety, and community ownership so that students can explore and develop unconventional ideas in a supporting environment.