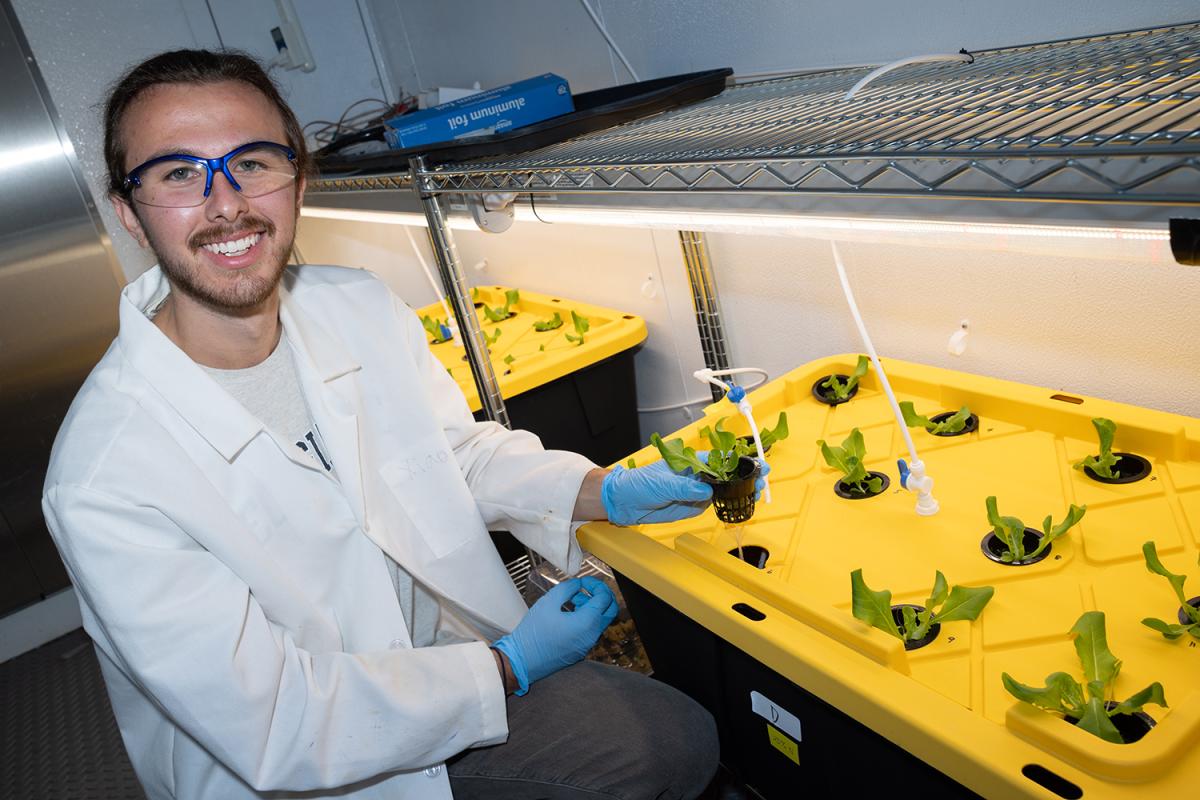

Yongsheng Chen examines lettuce growing in his lab’s vertical farm with first-year environmental engineering student Swathi Mugundu Pradeep (seated) and Ph.D. student Yuming Sun. (Photo: Candler Hobbs)

(text and background only visible when logged in)

Georgia Tech engineers are working to reduce the environmental impact of farming while creating technologies to help farmers feed a growing world and adapt to a changing climate.

(text and background only visible when logged in)

On the farms of the future, growers will be able to apply precisely the amount of fertilizer plants need at exactly the right time. And they’ll know just when to harvest the produce at peak nutritional value.

The result? Less fertilizer runoff to pollute waterways. Less water for irrigation. Less planet-warming emissions in a sector that accounts for a third of the world’s greenhouse gas generation.

That’s the vision Yongsheng Chen is working toward in a lab where robotic arms and state-of-the-art imaging systems are allowing him to capture data in unprecedented detail and create digital models of crops.

Using hundreds of images of each plant, Chen’s team in the School of Civil and Environmental Engineering builds representations in computers to map the relationship between the plant’s physical growth and its nutrient content. Understanding the connections will help him zero in on the perfect time to harvest the crops.

“For example, lettuce typically might grow for 20 to 28 days before harvest. Is the 28th day a good day to harvest? Or is it the 20th day? The model might tell you 20 days should be enough to get optimal nutrition,” said Chen, the Bonnie W. and Charles W. Moorman IV Professor. “That saves eight days’ time and resources, including energy and fertilizers. You can use that model to minimize the greenhouse gas emissions and other resources needed for agriculture.”

Harvesting lettuce or other crops at the peak moment ensures high quality produce. It also helps farms maximize their productivity. Growers can turn over fields at the optimal rate and avoid overburdening soil with too much fertilizer.

Overapplying fertilizers also wreaks havoc on downstream water bodies, where runoff can lead to overgrowth of plants in streams and lakes that cuts off oxygen for animal life in a process called eutrophication.

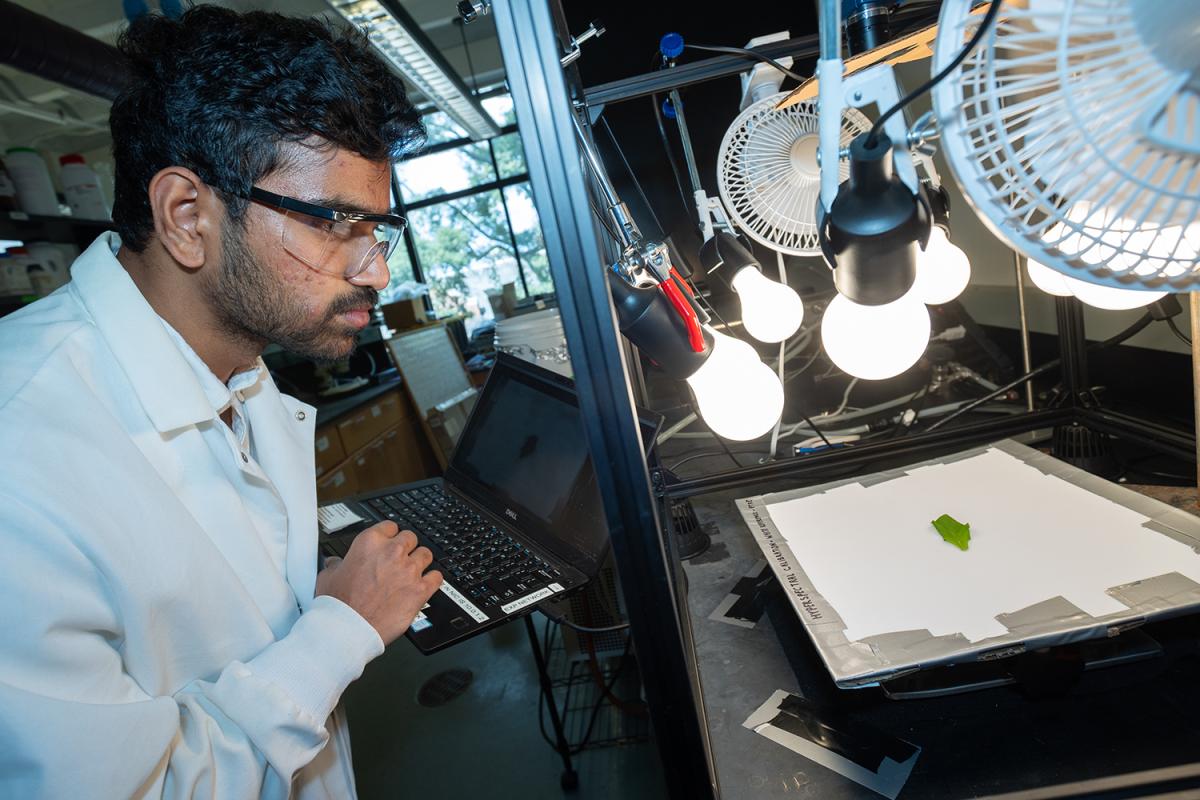

Computer science master’s student Harsh Muriki uses hyperspectral imaging to collect data about the nutrient content of a lettuce leaf. (Photo: Candler Hobbs)

This kind of pollution has contributed to a dead zone in the Gulf of Mexico every summer that can grow as large as New Jersey. The area is so devoid of dissolved oxygen in the water that fish and shrimp hightail it away. Slower or nonmobile marine life like crabs and clams are left to die.

In a related project, Chen is adding another layer of prevention. His team is adapting an innovation called neural radiance imaging to examine crops’ roots and study how they take in nutrients.

“We’re able to link the fertilizer uptake kinetics we see in the produce so that we can determine how much nutrient — fertilizer — is needed at different times, so that we can deliver fertilizers more accurately,” Chen said. “If you overdose the fertilizer, you end up with greenhouse gas generation, such as nitrous oxide, and rain-off from soil-based food production where all the fertilizer is washed into local rivers and lakes that become eutrophicated. That is not good. By investigating these root images, we’ll be able to deliver the nutrients more accurately.”

Ultimately, Chen said he wants to integrate those two approaches into a full digital agriculture system that would mean high productivity while allowing for maximum nutrition from crops.

For Chen, these issues are critical — and becoming more so. He’s one of a number of Georgia Tech engineers tackling agricultural sustainability in hopes of reducing waste and pollution while also feeding a growing world population.

These researchers are helping lead national efforts to turn waste into an asset, reduce runoff and recycle excess fertilizer, and greatly reduce the carbon impact of creating the nitrogen plants needs to thrive. They’re also working on technology to boost natural processes and help growers around the world adapt to a changing climate.

No More Wasting Wastewater

Chen sees wastewater as a key to addressing the challenges of feeding a growing and increasingly city-dwelling planetary population.

More than half of the world already lives in urban areas, and the United Nations projects it will grow beyond two-thirds by 2050. Meanwhile, the global population continues to increase, and food production must expand — by more than 50% by some estimates — to feed those people. To further complicate the picture, the U.N. Intergovernmental Panel on Climate Change suggests the expansion of cities will inevitably mean less land for crops, further suppressing food production.

Growing food produces lots of greenhouse gases. And those urban areas are already responsible for 70%-75% of emissions and energy use.

Chen and his team are developing an integrated and decentralized system of wastewater treatment and vertical farming that could address all of those issues, producing more food and turning a waste stream into a valuable resource.

Yongsheng Chen’s work on agricultural and urban sustainability includes studying hydroponically grown food and assessing its nutrient content. (Photo: Candler Hobbs)

“It’s very challenging. We have to shift the current paradigm from a unidirectional waste treatment approach to a more circular economy,” Chen said. “How do you do that? We propose recovering nutrients and water from wastewater so that we can grow produce within a city using vertical farming.”

In Chen’s vision, cities would capture and treat wastewater in multiple smaller locations rather than existing large, centralized treatment plants. Using a process his team is developing, the systems would recapture significant amounts of phosphorus, nitrogen, and ammonia, all key nutrients for growing crops.

The resulting “fertigation” water would both feed and water plants growing in compact, vertical farms co-located with the wastewater treatment systems.

With such a system, people have local food, cities have fewer issues dealing with the waste of growing populations, and, as a bonus, Chen’s approach virtually eliminates the carbon emissions from transporting produce across the country to feed mega population centers.

To see if the idea has legs, the researchers have done some ballpark estimates using the City of Atlanta’s three major wastewater treatment plants and a variety of representative crops — broccoli; leaf, romaine, and iceberg lettuces; spinach; bell peppers; tomatoes; and strawberries.

“We can grow enough vegetables to feed Atlanta’s 5 million plus population,” Chen said. “We don’t have to transport the vegetables from the West Coast. That is the beauty of this decentralized food production system.”

The proposed system also would recover additional water that could be used for industrial purposes and power plant cooling or further treated to become drinkable water again.

We have to shift the current paradigm from a unidirectional waste treatment approach to a more circular economy ... We propose recovering nutrients and water from wastewater so that we can grow produce within a city using vertical farming.

Yongsheng Chen

Chen and his collaborators have worked for several years to develop the technology to make the system work and grow safe-to-eat vegetables. Their efforts have included an on-campus test site harvesting wastewater from residence halls, extracting nutrients and water, and growing vegetables.

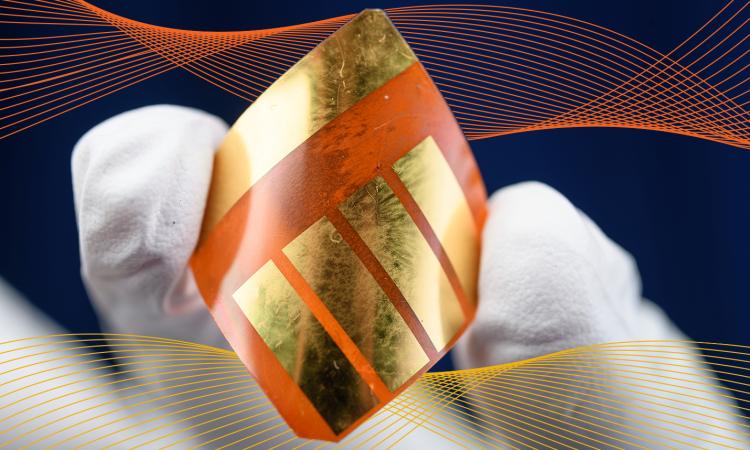

One of their key advances has been a unique membrane that effectively filters out contaminants while leaving the useful phosphorus, nitrogen, and water. Early results are promising: The membrane removed nearly 90% of contaminants like PFAS, often dubbed “forever chemicals,” as well as antibiotics and other pharmaceuticals. And while they haven’t tested for them, Chen said microplastics also should be filtered out of the resulting fertigation water.

The researchers continue to work on other membrane designs, too, using machine learning tools and decades of data from scientific literature to create a model that can suggest new materials. So far, they have a bank of eight promising membrane materials that should outperform current membranes. The team also is working to integrate their membrane filtration process into existing wastewater treatment systems.

Chen said his wastewater-to-vertical farm approach isn’t all that different from nature, where groundwater and surface water used to nourish crops on traditional farms contains waste from birds and animals along with antibiotics and other human-produced contaminants.

Still, much work remains to advance Chen’s technology to the point where it could serve large, urban areas. But he said the urgency is real, and the potential to solve many problems at once is compelling.

“There’s a huge mismatch within urban areas between demand for food and supply. If we decentralize the wastewater treatment and the food production within the city, we will be able to minimize this discrepancy,” Chen said.

“Plus, we can reduce the carbon emissions associated with food production and transportation as well as traditional wastewater treatment processes.”

(text and background only visible when logged in)

Closing the Fertilizer Loop

Marta Hatzell has her own ideas about turning wastewater into something valuable.

One project in her lab is exploring how to recover raw materials from the waste and produce urea, the most widely used nitrogen-based fertilizer. Typically, urea is manufactured commercially by creating ammonia and then combining it with carbon dioxide.

Instead, Hatzell’s system would create urea fertilizer using CO2 scrubbed from the atmosphere at a direct air capture facility and pairing it with nitrates recovered from a wastewater treatment plant.

“The idea is that capturing carbon dioxide gives us this solution rich in CO2. Can we then merge that with wastewater that’s rich in nitrate and do a catalytic process that converts it directly to urea? If we could, that would be a carbon-negative process. And then we also would not have to make fresh ammonia to make urea,” said Hatzell, Woodruff Associate Professor in the George W. Woodruff School of Mechanical Engineering and the School of Chemical and Biomolecular Engineering.

Direct air capture systems are becoming an increasingly popular idea for removing carbon from the air and storing it underground or finding ways to reuse it. Georgia Tech has been a hub for developing the approach, with the world’s foremost experts in the technology. Hatzell said it wouldn’t be unrealistic to imagine a direct air capture system co-located with a municipal wastewater treatment plant, making it easy to draw from the streams of CO2 and nitrate-rich waste.

Hatzell spends much of her time thinking about fertilizer — better ways to create it and new approaches to recycling or reclaiming the excess after use. Her goal is to reduce the carbon impact of a critical tool for food producers trying to feed more people.

She has developed processes that use light to produce ammonia at ambient temperature and pressure using far less energy than current high-temperature, high-pressure practices. Her team has created new chemical catalysts to convert waste fertilizer back into harmless nitrogen that also could serve as raw material for new fertilizer.

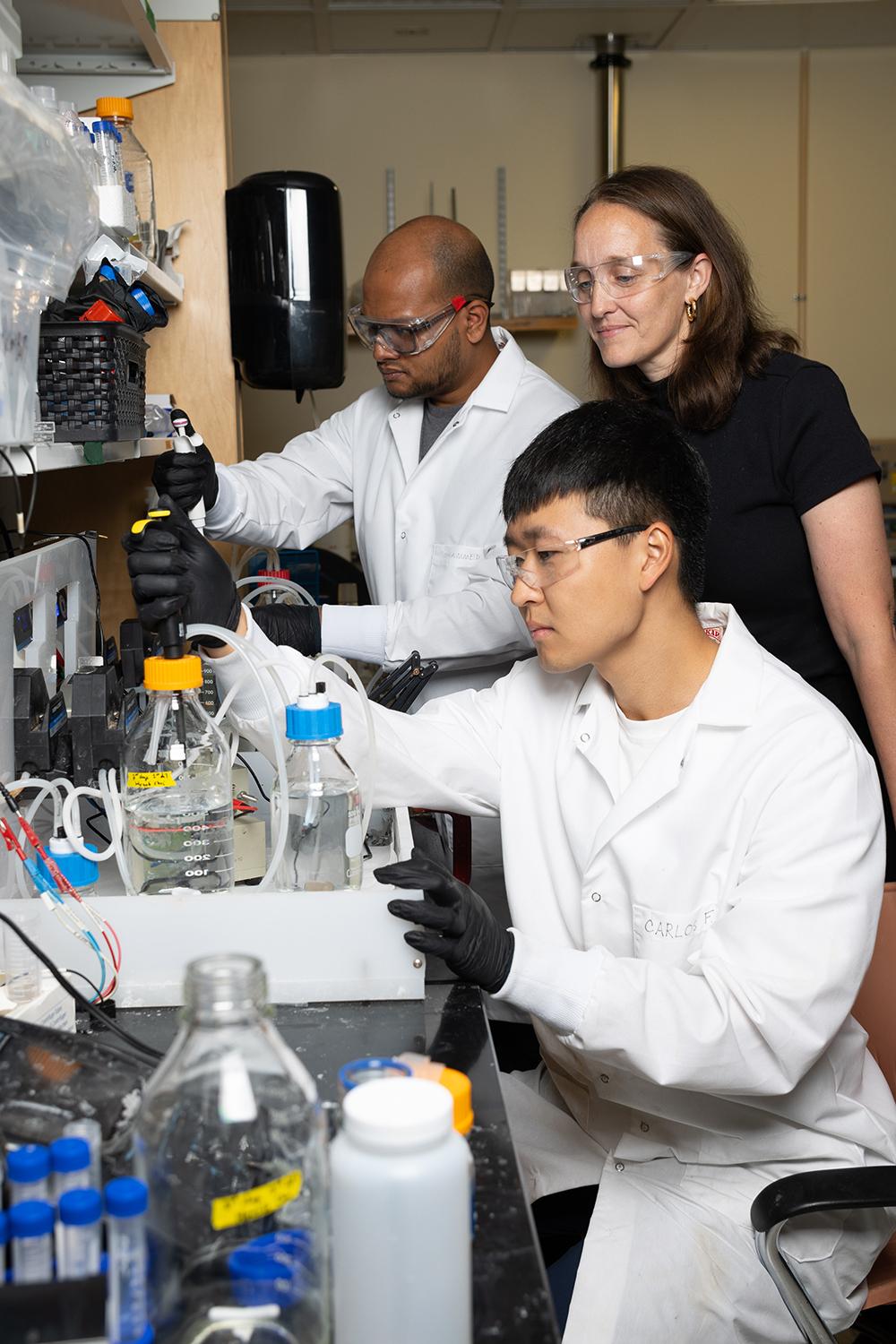

Marta Hatzell’s lab is developing processes to extract reusable ammonia from waste at livestock farms. Ph.D. students Mohammed Tahmid (standing) and Hyuck Choi are among the researchers working with her to use electricity and special filtering membranes to recover the useful nutrient. (Photo: Candler Hobbs)

These and other projects in Hatzell’s lab are aimed at reducing agriculture-related emissions upstream, metaphorically, of the actual farming and waterway pollution literally downstream.

Some of her newest work would tackle both ends of that spectrum for livestock farms, or concentrated animal feeding operations in industry parlance. Hatzell is working to recover valuable compounds from animal waste with a relatively inexpensive process that yields clean, nutrient-rich water that can be used — like Chen’s nutrient-rich water — for crop fertigation.

“We’ve demonstrated the ability to get really high recovery of the nutrients that we want, at high weight percents, and at a reasonable cost,” Hatzell said. “That is always the challenge with nutrient recovery systems. For agriculture, you have to have low cost and high recovery, and you have to do it with energy efficiency.”

Hatzell’s targets are storage lagoons where waste collects from animal farms. Normally, biological processes slowly decompose the waste.

Her team instead would use electricity and special filtering membranes to extract useful ammonia from the waste. Their process would produce 90% purified water and 10% ammonia, with contaminants like PFAS, pathogens, and antibiotics stripped out.

CASFER

Hatzell is one of the Georgia Tech researchers leading a National Science Foundation-funded center focused on resilient and sustainable food production. The Center for Advancing Sustainable and Distributed Fertilizer Production (CASFER) includes four other universities working to decarbonize nitrogen-based fertilizers and develop the next generation of fertilizer technology.

“At the end of the day, you would get this pure water-plus-ammonia mixture,” Hatzell said. “We could crystallize that out to make solid fertilizers like ammonium phosphate or ammonium nitrate. But we think it’s best to just connect that ammonia water to an irrigation system and deliver it as a liquid fertilizer.”

Why is ammonia so important? It’s the fundamental building block for fertilizers, replenishing nitrogen in the soil that plants quickly deplete as they grow. The air we breathe is mostly nitrogen, but not in a form that’s biologically or chemically useful. Combining it with hydrogen to create ammonia allows it to react with soil and feed plants.

Producing ammonia isn’t all that easy. It requires significant petroleum-based energy and can only be done at 100 or so large-scale facilities worldwide because of the high temperatures and pressures required. That also means fertilizer is usually produced as solid granules that are easier to ship around the world.

Transporting liquid like Hatzell’s water-ammonia fertilizer is much more challenging — distribution would have to be across tens of miles rather than hundreds to be worthwhile. Yet the benefits could be substantial, she said.

In addition to dealing with problematic livestock waste lagoons, liquid fertilizer application can be much more precise than a few blanket applications of solid granules every year. With automation, artificial intelligence, satellite imaging, and robotics, Hatzell said engineers can design systems that precisely apply the right amount of nutrients alongside the right amount of irrigation at just the right time. And that’s far easier to control than granular products.

The results would be less waste, more food, and maybe even value for farmers from what can be a cost center now. Sometimes they have to actually pay to dispose of the animal waste that has collected.

But this all would mean big changes in how things are done.

“It’s changing what a fertilizer looks like: Instead of starting with pure, virgin feedstocks, let’s start with waste that is accumulating at agricultural sites,” Hatzell said. “That’s the first paradigm shift. The second is to move from the solid, granular, salt-based fertilizers to a liquid-based fertilizer. And then that creates more circularity.”

“Circularity” is a key driver of Hatzell’s work. It means converting the nitrogen production cycle from a straight line into a circle, where waste isn’t wasted anymore.

“I think there’s such a good economic and societal motivator for coming up with technologies to deal with waste,” Hatzell said. “That’s why we started to work in this space. There’s an economic need, an engineering need, and a societal need.”

(text and background only visible when logged in)

(text and background only visible when logged in)

Boosting Nature’s Process

A project getting underway spanning Atlanta and Chile involves chemical and biomedical engineers working to speed up and amplify natural processes rather than recovering or reusing materials. The goal is to help farms be more productive, even in the face of a changing climate.

Lily Cheung and Shu Takayama spent a week this summer with partners and farmers in the South American country to understand their needs and approach to farming. With support from the National Science Foundation (NSF), the pair of Georgia Tech engineers aim to develop biomaterials or natural polymers that can help retain water in the soil, speed up creation of compost, fight pathogens, and perhaps increase the availability of phosphate for plants.

It’s not what they originally had envisioned when they set out to design a project for the NSF’s Rules of Life research program, but that was the whole point of their visit to Chile — to discover what farmers truly needed before they created solutions.

Takayama and Cheung at one of the farms they visited during their trip. (Photo courtesy: Lily Cheung / Shu Takayama)

The research group visiting a greenhouse owned by one of the small farms in Chile. (Photo courtesy: Lily Cheung / Shu Takayama)

Chile is an excellent proving ground, Cheung said, because the country has a range of agricultural operations, from small subsistence farms all the way up to industrial crop production. The materials or processes the researchers create with their Chilean collaborators will be useful for American agriculture and farms in other parts of the world, too.

“Water is a problem, nitrogen is a problem, phosphate is a problem,” said Cheung, assistant professor and Roy C. and Polly B. Sheffield Faculty Fellow in the School of Chemical and Biomolecular Engineering.

“We’re working to help small farmers without having to rely on external inputs and non-agroecological practices. For example, how do we make composting faster? That was one question that we started thinking about during our visit. It was not in the original conception of the project, but if it’s what a small farmer needs, then that’s what we need to think about.”

Lily Cheung and Shu Takayama with an aquaculture researcher in his lab at the University of Chile. (Photo courtesy: Cheung / Takayama)

Cheung said they discovered small subsistence farmers can get all the nitrogen they need from compost. Medium-sized farms, on the other hand, might benefit from the team creating new biomaterials to encourage the growth of microbes that infuse more nitrogen into the soil through a process called nitrogen fixation.

Takayama said they were struck in Chile by how much climate change has altered the landscape for many farmers. For example, land that used to be fine without irrigation now requires extra water, yet the infrastructure isn’t in place to support it.

The Covid-19 pandemic also limited the availability of fertilizer for many farmers in Chile, so there’s a strong desire to eliminate the need for that kind of expensive, imported material.

“We had this idea about nitrogen fixing, but we went there and found climate change, water, and pathogens are huge problems,” said Takayama, professor and Price Gilbert Jr. Chair in the Wallace H. Coulter Department of Biomedical Engineering. “The individual farms are so small — they have a little bit more than an acre, and they raise their whole family from that using hardly any equipment and minimal external inputs like fertilizers or pesticides because of the high costs. It completely changed the perspective of what we’re trying to do.”

Takayama said the team is exploring simple polymers like swelling hydrogels that could retain and slowly release water to help with drought issues. On a more fundamental level, he also wants to understand how different polymers, materials, and bacteria impact soil microstructure. Facilitating the right soil structure could be key to boosting microbial nitrogen fixing processes as well as harboring microbes that make phosphate soluble and available for growing plants.

The Georgia Tech team’s collaborators include global environmental science and governance scholar William San Martín at Worcester Polytechnic Institute, soil engineer Osvaldo Salazar at the University of Chile, and Sigrid Vargas from Chile’s Institute of Agriculture Research. They’re also working with a network of government agriculture extension professionals who will share their findings with farmers across the country.

Cheung said they learned from these professionals that it will be key to set up demonstrations to show farmers the effectiveness of whatever solutions they design. That, along with more detailed conversations with farmers, will be the subject of future trips during the five-year project.

Cheung said they’re working with a real sense of urgency, because they’ve seen how critical it will be for farmers in Chile — and other parts of the world — for them to develop practical solutions.

“It’s tough research. It will take some years,” she said. “But we have to deliver.”

(text and background only visible when logged in)

(text and background only visible when logged in)

Related Stories

Powering Up

Our researchers are creating new technologies that pollute less and store more energy — while also ensuring the manufacturing process is clean.

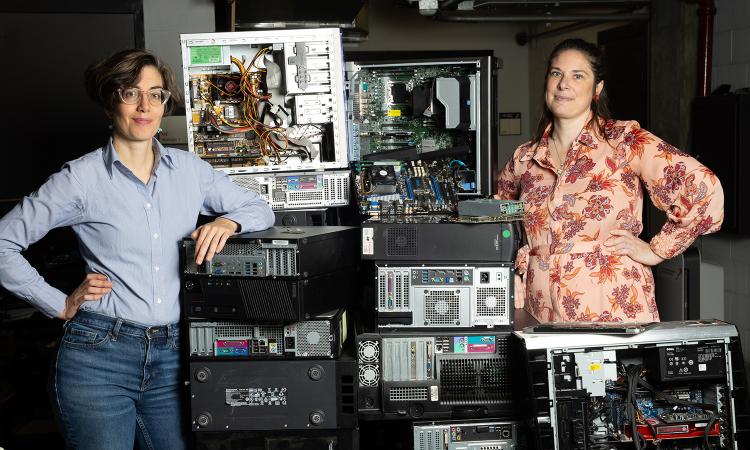

To Hell with Garbage

In the quest to reduce, reuse, and recycle, Georgia Tech engineers are at work on ways to divert more trash from landfills, tame plastic pollution, and cut waste from electronics.

Why Equitable Sustainability Matters

Growing up in a Midwestern inner city led Joe Bozeman to a career understanding how sustainability takes shape for people of many different backgrounds.

(text and background only visible when logged in)

Helluva Engineer

This story originally appeared in the Fall 2024 issue of Helluva Engineer magazine.

In a world with more people, more energy needs, and more waste than ever, Georgia Tech engineers are hard at work developing the tools and technology for everyone to thrive. We’re diverting trash from landfills and taming plastic pollution (while finding alternatives to plastic in the first place). We’re reducing the environmental impact of agriculture and finding new ways to fertilize the fields growing food for a growing world. And engineers are powering up the batteries, fuels, and renewable sources to meet surging energy demand. The future is coming; we’re making it more sustainable.